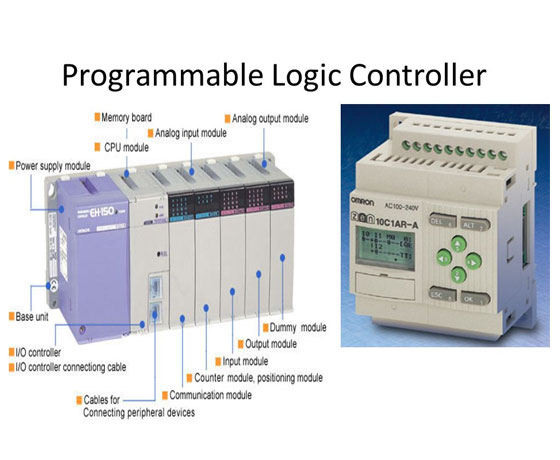

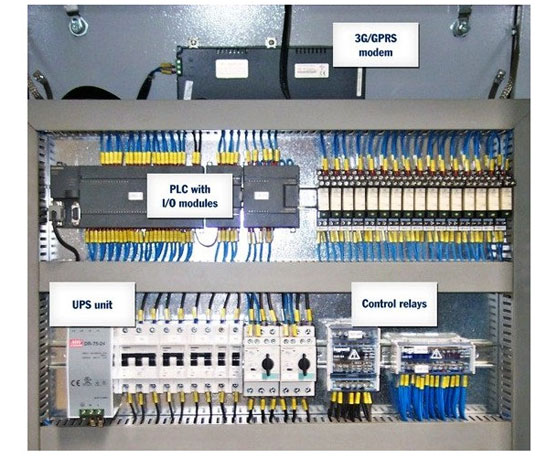

Schneider DDC Controller PLC (Programmable Logic Controllers) has become the soul of industrial automation as it is the hardware component directly in contact with the field instruments. It gives access to control and monitors the array of connected machinery and the software system integrated with it. The PLC system can work with a variety of communication protocols like data conversions, i/o interfacing, signal processing, etc.

The system is user programmable, i.e., you can set triggers on different parameters like temperature, liquid level, opening or closing of valves, etc. It can be used in the simplest of devices like garage doors to complex systems like a powerhouse.

A Programmable Logic Controller, or PLC, is a ruggedized computer used for industrial automation. These controllers can automate a specific process, machine function, or even an entire production line. The PLC receives information from connected sensors or input devices, processes the data, and triggers outputs based on pre-programmed parameters.

Depending on the inputs and outputs, a PLC can monitor and record run-time data such as machine productivity or operating temperature, automatically start and stop processes, generate alarms if a machine malfunctions, and more. Programmable Logic Controllers are a flexible and robust control solution, adaptable to almost any application.

A PLC (Programmable Logic Controller) control panel contains electrical components such as relays and switches, that run factory machines or processes in single or multiple networks. They are small but powerful computers that are integrated into your control panel and are capable of tracking and analyzing any process with the information available at your fingertips.

PLCs are easy to operate, and they work to boost your facility’s output while also improving energy efficiency and decreasing costs. The programming can easily be changed to adjust to new facility needs, as opposed to having to switch out wiring or hardware

Flow meters measure the quantity of a fluid passing through a pipe or channel in any state such as liquid, gas, or steam. The flow meter is calibrated for a specific set of conditions and cannot measure two states simultaneously. Older technology flow meters, such as turbine meters or positive displacement meters, typically consist of a primary mechanical device such as a rotating turbine or set of gears, a transducer to convert the mechanical action into an electrical signal, and a transmitter to process and send the signal to a receiving device such as a computer or PLC.

In this type of design transducer or a sensor detects the fluid velocity and sends a raw signal to an embedded microprocessor integral to the flow meter which manipulates the signal into various meaningful outputs.

Being the leading names in the industry, we offer our clients a wide range of Water Meters that are acclaimed among the clients for their high calibration and accurate functionality. We offer them in different grades and dimensions and can be customized as per the Due to our honest business standards and transparent deals, we are steadily making our way to the platform of success by offering a superior grade range of Water meters.

Our products are appreciated for long serviceability as our products are made from the raw material fetched from our admired vendors and are designed for long durability, non-corrosive and compact design so that the product looks evenly completed and can be easily installed.

Energy Meters

Energy consumption awareness is key to reducing energy costs and improving energy efficiency on your machines and electrical assets. Energy meters allow the identification of areas for improvement and generate benefits for owners, facility managers, and users.

They enable us to run smarter buildings in a more energy and cost-efficient manner. Sub-metering provides a detailed picture of energy consumption and the specific areas where energy is used.

Industrial Automation is the use of various control systems for operating machinery in factories with minimal or reduced human intervention. Today, Factory Automation is transitioning to its 4th revolution commonly referred to as Industry 4.0, and is therefore a major part of the megatrend of Industrial IoT (IIoT).

Automation has been achieved by various means including mechanical, hydraulic, pneumatic, electrical, electronic devices, and computers, usually in combination. Modern factories typically use all these combined techniques. The benefit of automation includes labor savings, savings in electricity costs, savings in material costs, and improvements to quality, accuracy, and precision.

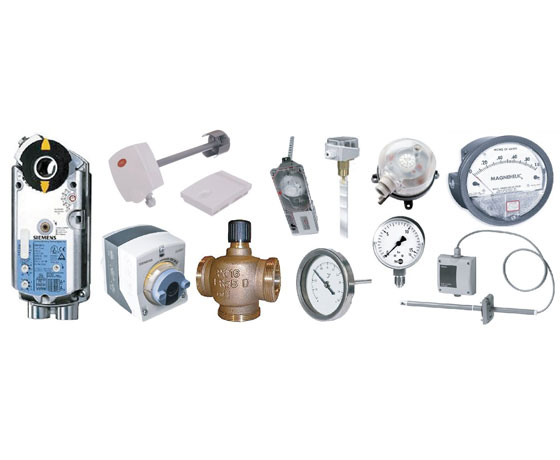

Relays and actuators are important hardware parts of an embedded system. While an actuator acts as a device that helps to bring about necessary mechanical movements a relay basically works as a switch. The actuator constitutes two distinct modules which are the signal amplifier and the transducer.

While the amplifier converts the low-power control signal into a high-power signal the transducer converts this amplified signal into the required energy form. Switches are very commonly used devices but they have several disadvantages when compared to other similar devices available in the market.